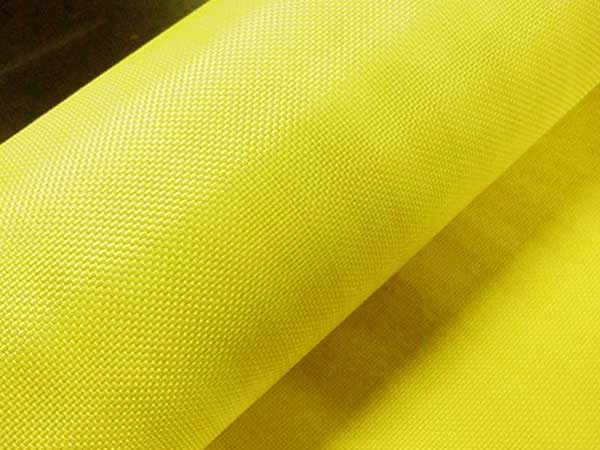

Para-aramid twisted yarn is made from para-aramid fibers through a twisting process. By twisting para-aramid fiber, it can not only increase the strength and stability of the yarn, but also improve its textile processing properties, making it more suitable for weaving, knitting or blending with other materials to meet the needs of different application fields.

Rubber reinforcement, textiles, protective equipment, friction materials, etc.

| Line Density(Dtex) | Twist(TPM) | Maximum Load(N) | Elongation at Break(%) |

| 660 | 150±10 | ≥130 | ≥3 |

| 930 | 130±10 | ≥185 | ≥3 |

| 1100 | 120±10 | ≥220 | ≥3 |

| 1670 | 90±10 | ≥330 | ≥3 |

| 2520 | 70±10 | ≥520 | ≥3 |

Products made from para-aramid fibers offer excellent resistance to cutting, puncturing, abrasion, high temperatures, as well as low density and superior electrical insulation properties. For example, gloves made from para-aramid fibers are 2 to 3 times stronger than high-strength polyester or polyamide gloves, with a cut resistance rating of level 5 (according to the European standard EN388).

Extremely High Strength: Para-aramid fiber offers extremely high tensile strength, significantly surpassing that of typical synthetic and natural fibers, making it an ideal material for high-strength reinforcement.

Good Temperature Resistance: It retains stable physical and mechanical properties within a specific temperature range, demonstrating excellent resistance to high temperatures and being non-flammable.

Excellent Chemical Resistance: Para-aramid fiber is highly resistant to a wide variety of chemicals, ensuring durability in harsh environments.