Para-aramid pulp is a powder or slurry product derived from para-aramid (poly-p-phenylene terephthalamide) fibers through specialized processes such as mechanical grinding and chemical treatments.

It can be used as a reinforcing filler in resin-based composite materials, significantly enhancing their mechanical properties. It is particularly well-suited for producing structural components that demand high strength, thermal stability, and corrosion resistance.

Additionally, para-aramid pulp can be further processed into a pre-dispersion, which can be incorporated into polymer materials like rubber and plastic to improve the strength and durability of the final products.

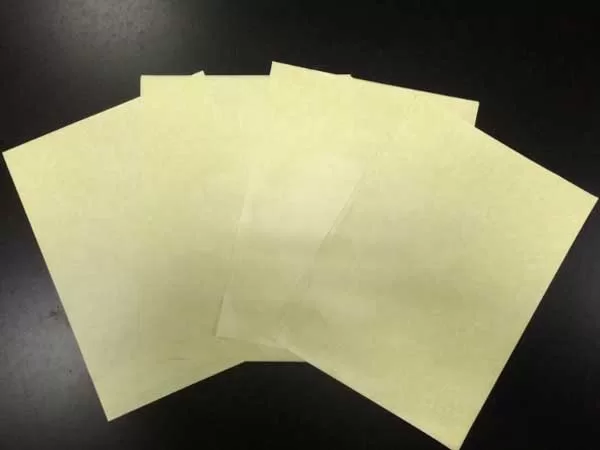

Specialty paper manufacturing, textile reinforcement, friction materials, construction materials, etc.

| Variety | Moisture Content(%) | Shaw’s Beating Degree(°SR) | Fiber Length(mm) | Specific Surface Area(㎡.g⁻¹) |

| 1820 | 4~9 | 30~40 | 0.85~1.35 | 5~12 |

| 1427 | 4~9 | 35~50 | 0.75~1.15 | 5~10 |

| 1628 | 4~9 | 45~60 | 0.65~1.05 | 5~10 |

| F1128 | 4~9 | 25~45 | 0.70~1.40 | 5~13 |

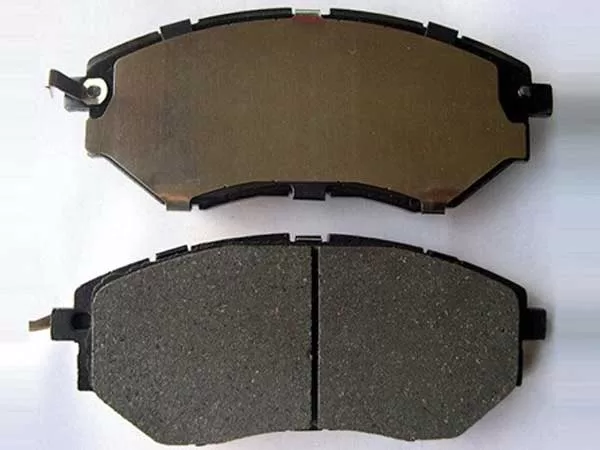

Brake pads processed with para-aramid pulp offer excellent wear resistance and high-temperature stability, serving as an effective alternative to asbestos. Adding only 5% para-aramid pulp has the same performance as using 20% asbestos, which not only reduces brake noise but also improves wear resistance, thereby shortening braking distance, extending service life, and reducing replacement times.

High Strength and High Modulus: Para-aramid pulp retains the high strength and high modulus properties of the original para-aramid fiber. Even in its pulp form, it continues to deliver significant improvements in the mechanical properties of composite materials. The material boasts outstanding tensile strength and impact resistance, making it ideal for demanding applications that require enhanced durability.

High Temperature Resistance and Flame Retardancy: Para-aramid pulp performs exceptionally well in high-temperature environments, offering excellent heat resistance and flame retardancy. It helps prevent the spread of fire and reduces the generation of harmful smoke, providing an added layer of safety in applications exposed to extreme heat.

Chemical Stability: Para-aramid pulp demonstrates excellent resistance to acids, alkalis, and other chemical agents. It remains stable even in highly corrosive environments, resisting degradation or corrosion from various chemical substances.

Electrical Insulation Properties: It has good electrical insulation properties and can be used as a high-performance electrical insulation material.

Dispersibility and Compatibility: After specialized treatment, para-aramid pulp disperses evenly in various matrix materials, showing excellent compatibility with polymers such as resins and rubber. This facilitates the creation of composite materials with balanced performance and stable structural integrity.

Processing Adaptability: According to different application requirements, para-aramid pulp can change its distribution state and interface bonding force in composite materials by adjusting particle size and surface treatment methods, thereby optimizing the overall performance of composite materials.

Environmental Performance: After the life cycle of para-aramid pulp ends, its waste will cause relatively little pollution to the environment, and some products have the potential for recycling and reuse.